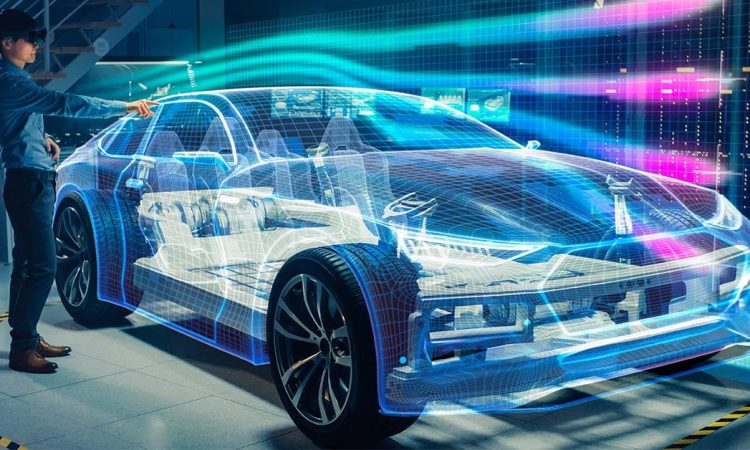

Efficient prototyping births great products. Thanks to virtual prototypes, designers, engineers, and manufacturers can improve the quality of their creations. They can conduct digital simulations before developing physical prototypes, thus reducing errors and wastage while enhancing iterations.

Virtual prototyping refers to the use of software to create a product’s representation before building it. Compared to the conventional physical prototype, a virtual prototype leverages the digital environment to simulate real-world conditions. Therefore, you can see how an idea translates in real life before developing it. Prototyping is critical in the product development cycle, and the convenience of virtual settings sets the stage for better innovations. The following is a look at some of the elements that make virtual prototypes crucial to the creation of new products.

Supports Rapid Iteration

By the time an idea becomes a product in the market, it goes through many changes. One goal of prototyping is to make room for iterations. When testing a prototype, you can see how well the idea meets its requirements. Designers can adjust the size, shape and features to ensure a product adheres to its specifications. The scientific approach of virtual prototyping favours precision, allowing for quick iterations with minimal wastage. Engineers and designers only have to change the specifications in a digital environment, as opposed to creating a new prototype. Effective iteration leads to optimisation and highly innovative products built to exact specifications.

Error Reduction

The digital testing of products makes it easy to spot mistakes. Designers and engineers can identify errors early in virtual prototypes. They can simulate numerous real-world scenarios to see how well a product adapts. Virtual prototyping allows for thorough testing to expose design flaws. Timely error detection leaves room for correction before committing to physical prototypes. It also eliminates the need for expensive reworks. Digital prototypes also help with quality improvement. Engineers can fix errors to ensure maximum performance, leading to reliable innovations.

Promoting Collaboration and Creativity

Evaluating products virtually before developing their physical representations enhances collaboration between different teams. A product’s life cycle, from idea to manufacturing, involves varying experts. These professionals must work together to move from imagination to reality. Digital prototyping provides a shared platform where multidisciplinary teams can communicate easily. Engineers can point out flaws to designers without the need for physical contact. Teams in remote locations can contribute to a project comfortably online. The diverse perspectives of different experts foster creativity. They can share ideas easily, resulting in top-tier products.

Cost Reduction

Quick detection of flaws, fast time-to-market and efficient team communication all result in low product costs. Manufacturers can save money and resources in several areas. These savings can be allocated to exploring new concepts. Innovation requires significant investment, and virtual prototyping allows for that without short-changing product quality.

Product manufacturing is a fast-paced industry driven by innovation. It demands that stakeholders, like engineers and designers, create quality products in short time frames. Virtual prototyping provides for this by slashing development times, accelerating iterations and decreasing wastage. By incorporating virtual prototypes in the development cycle, manufacturers can bring top-notch products to market with unrivalled efficiency.