In modern manufacturing and product development, ensuring quality and reliability is non-negotiable. Two critical processes often mentioned together—composite testing and testing validation—play unique roles in achieving these goals. While they might sound similar, these methods address different stages of the quality assurance journey. Understanding their distinctions and best practices can help organizations reduce risk, streamline production, and deliver superior products to market.

Understanding Composite Testing: Verifying Material Strength and Performance

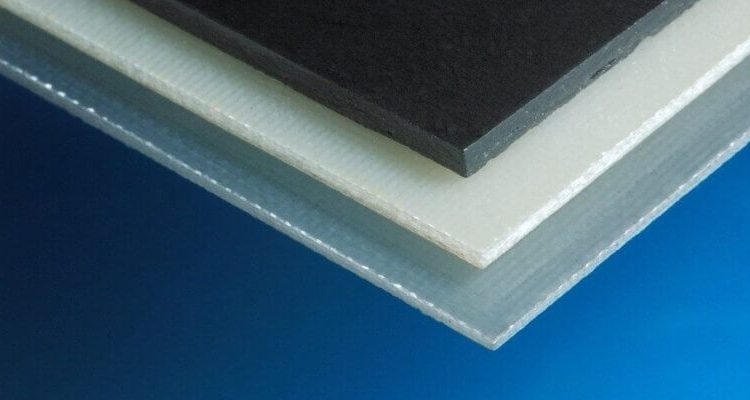

Composite testing focuses on evaluating composite materials—those created by combining two or more constituent materials, such as carbon fiber reinforced polymers, fiberglass, or advanced ceramic composites. These materials are prized for their strength-to-weight ratio, corrosion resistance, and flexibility across industries like aerospace, automotive, marine, and renewable energy.

A robust composite testing program typically includes:

- Mechanical Testing:Tensile, compressive, and flexural tests to measure strength, stiffness, and elasticity.

- Environmental and Thermal Testing:Simulating extreme temperatures, humidity, or UV exposure to assess durability.

- Non-Destructive Evaluation (NDE):Techniques such as ultrasonic scanning or X-ray imaging to identify hidden defects without damaging the sample.

The goal is to confirm that the composite material meets or exceeds the specifications required for its intended application. For example, aerospace components must endure significant stress and temperature fluctuations without failure. Rigorous composite testing ensures that each batch of material behaves predictably, reduces structural failures, and meets regulatory standards.

Beyond compliance, composite testing offers strategic advantages. By understanding a material’s performance envelope, engineers can innovate confidently—designing lighter, stronger, and more efficient products. This is particularly valuable in competitive markets where reducing weight or increasing durability can translate into significant cost savings and performance benefits.

Exploring Testing Validation: Proving a Process or Product Works as Intended

While composite testing focuses on materials, testing validation is broader and process-oriented. It involves confirming that a product, system, or manufacturing process consistently produces results that meet predetermined requirements and regulatory standards. In other words, validation answers the question: Does it work as intended under real-world conditions?

Key components of testing validation include:

- Installation Qualification (IQ):Verifies that equipment or systems are installed correctly.

- Operational Qualification (OQ):Confirms that the system operates according to defined parameters.

- Performance Qualification (PQ):Demonstrates that the process delivers consistent, reliable results during routine operations.

Industries such as pharmaceuticals, medical devices, food production, and software development rely heavily on testing validation. For instance, a pharmaceutical company must validate its production line to prove each batch of medicine is safe, potent, and consistent. In software engineering, validation ensures that a product meets user needs and regulatory compliance before release.

The advantages of testing validation extend beyond regulatory compliance. Effective validation minimizes production downtime, prevents costly recalls, and boosts customer trust. It also provides valuable documentation and traceability, which are crucial during audits or when scaling up production.

Key Differences Between Composite Testing and Testing Validation

Although both processes aim to ensure quality, they diverge in scope, focus, and application:

- Scope:Composite testing targets material properties, while testing validation verifies entire processes or products.

- Purpose:Composite testing ensures that materials meet strength and performance specifications; testing validation ensures that systems consistently deliver the intended outcome.

- Timing:Composite testing is often performed during material selection or early production, whereas testing validation typically occurs before full-scale manufacturing or product launch.

In practical terms, a manufacturer of carbon fiber bicycle frames might perform composite testing to evaluate material strength and fatigue resistance. Once the production process is defined, the company would then conduct testing validation to ensure every frame manufactured on the assembly line meets quality standards and regulatory requirements.

Best Practices for Implementing Both Methods

To maximize efficiency and compliance, organizations should adopt the following best practices:

- Establish Clear Requirements Early

Define performance criteria and regulatory standards from the outset. Clear documentation reduces ambiguity and streamlines both composite testing and validation efforts. - Leverage Accredited Laboratories and Tools

Partnering with certified labs ensures accurate results and adherence to industry standards such as ASTM, ISO, or FDA guidelines. - Integrate Testing into the Design Phase

Incorporating testing and validation early in product development helps identify potential weaknesses before full-scale production, saving time and resources. - Maintain Comprehensive Records

Thorough documentation supports traceability, simplifies audits, and facilitates continuous improvement. - Embrace Automation and Digital Tools

Using advanced data acquisition systems, AI-based analysis, and digital twin simulations can reduce human error and accelerate decision-making.

Conclusion: Complementary Roles in Quality Assurance

Composite testing and testing validation are not interchangeable—they are complementary. Composite testing assures the strength and reliability of materials, while testing validation ensures that products and processes function as intended. Organizations that invest in both will gain a competitive advantage by delivering safer, higher-quality products to market more efficiently.

By recognizing their unique purposes and following best practices, manufacturers, engineers, and quality assurance teams can create a robust framework for innovation and compliance. Whether you’re designing lightweight aerospace components or validating a pharmaceutical production line, understanding these two critical processes is key to long-term success.